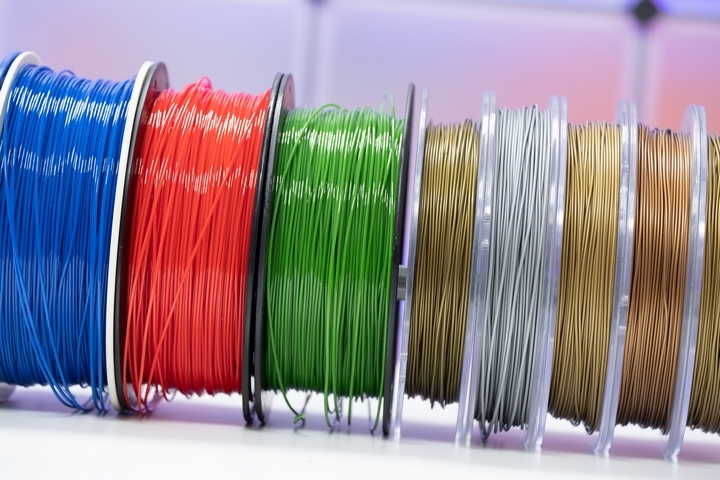

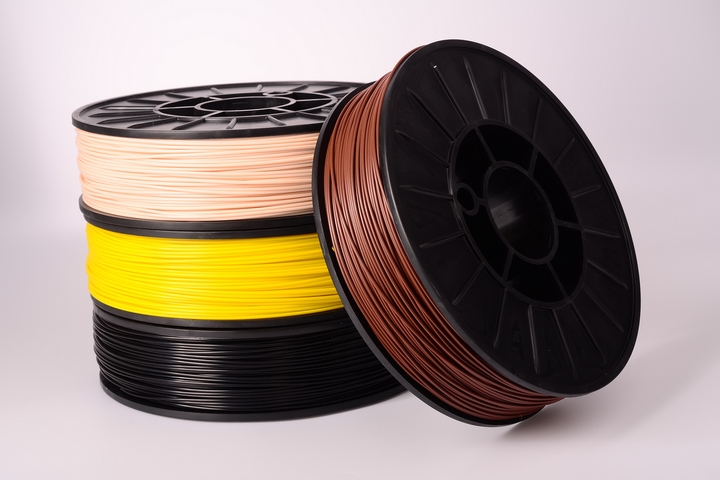

As 3D printing becomes more popular, there is an ever-increasing number of 3D printer filament types being introduced onto the market. Each 3D printer filament type has something different to offer, and each one has its own unique drawbacks as well.

Are you a 3D printer enthusiast who want to learn more about these different filament types? Here are the twelve different 3D printer filament types and their respective uses:

Type #1: Acrylonitrile Butadiene Styrene (ABS)

ABS filament has a higher temperature resistance than other filaments and is good for electrical insulation. It is also a flexible material, meaning it can bend further than some other materials before cracking or snapping. This type of filament is strong, and is a good, structural material. ABS is not toxic, although the fumes that are associated with its use are very strong.

Type #2: Polylactic Acid (PLA)

This is one of the most common 3D printer filament types used. It is well-liked because it is easy to access and easy to print with. It is not an ideal printing material for building things that will be bearing any kind of load, as they will become deformed in the long-term. Another awesome feature of PLA is that it is biodegradable, making it one of the more earth-friendly options.

Type #3.: Polyethylene Terephthalate Glycol-modified (PETG)

The best of both PLA and ABS, PETG is a strong and heat-resistant material that prints easily. It is one of the main 3D printer filament types that people opt for due to its versatility.

The best of both PLA and ABS, PETG is a strong and heat-resistant material that prints easily. It is one of the main 3D printer filament types that people opt for due to its versatility.

However, even with all of its benefits, PETG is not a perfect material. It tends to stick to the nozzle, which has meant that companies have had to come up with alternative types of nozzles to help counteract the filament sticking when dispensed.

Type #4: Conductive PLA

This type of PLA filament is designed to allow electricity to be conducted, so it is good for use in low-voltage or low conductivity applications. It can be used on any printer that would support PLA filament. Although slightly more flexible than PLA, it is a fairly stiff material that will break if bent repeatedly. As such, pieces made with conductive PLA are not typically meant to be flexed and bent.

Type #5: Magnetic Iron PLA

Made from PLA combined with iron powder, this filament is ferromagnetic – meaning magnets will be attracted to it (but is not a magnet itself). The strength of magnetic iron PLA is comparable to regular PLA, and prints very similarly as well, other than printing better at a slightly cooler temperature than what would normally be used.

Type #6: Polyvinyl Alchol (PVA)

PVA is an interesting material, because its main feature is that it is water soluble. This can be a very useful feature for building molds or temporary structures. PVA is one of the 3D printer filament types that is considered more earth-friendly, as it is biodegradable and non-toxic.

PVA is an interesting material, because its main feature is that it is water soluble. This can be a very useful feature for building molds or temporary structures. PVA is one of the 3D printer filament types that is considered more earth-friendly, as it is biodegradable and non-toxic.

It also does not require oil in manufacturing, which makes it more earth friendly than other materials. That said, PVA is difficult and finicky to work with, and isn’t really recommended unless required for its solubility.

Type #7: Polyvinyl Butyral/Polysmooth (PVB)

This type of filament exists to work with a machine that helps to automatically smooth the surfaces of a 3D print. The machine smooths the prints using isopropyl alcohol, decreasing the amount of time spent post-printing trying to smooth out the surfaces. PVB cannot be used in environments that require use in high temperatures, as it will become deformed.

Type #8: Butanediol Vinyl Alcohol Copolymer (BVOH)

This is a water-soluble material which is used when printing with PLA. One of the main drawbacks of it is that it can be pretty pricy – it’s not a material to be wasted.

Type #9: Nylon

In general, nylon is one of the more difficult 3D printer filament types to work with, but it is non-toxic and heavy duty. Nylon can handle being hit, dropped, or struck better than other filaments. The material by itself is more flexible, but fillers can be added to stiffen it up.

In general, nylon is one of the more difficult 3D printer filament types to work with, but it is non-toxic and heavy duty. Nylon can handle being hit, dropped, or struck better than other filaments. The material by itself is more flexible, but fillers can be added to stiffen it up.

However, when combining nylon with fillers, some of its durability will be lost. It is an inexpensive material, but requires high amounts of heat, and a heated print bed.

Type #10: Thermoplastic Polyurethane/Thermoplastic Elastomer (TPU/TPE)

These are some of the most flexible filament types available. TPU/TPE don’t provide as much structural durability as other filaments, but they are impact resistant. The biggest drawback of TPU/TPE is that it is not heat resistant. Once the item is printed, if it is used in an environment with too much heat, it will lose its shape and warp.

Type #11: High-density polyethylene/high-impact polystyrene (HDPE/HIPS)

Essentially a lighter and stronger replacement for ABS, HDPE, also known as HIPS, is easily dissolved in limonene, but does require higher printing temperatures than ABS. It can be used with any printer that is compatible with ABS.

Type #12: Wood

Wood filament is a PLA-based filament combined with wood fibers, typically split up into 70 per cent PLA and 30 per cent wooden fibers. The fibers can come from several different types of wood including, but not limited to, bamboo, cedar, and birch. Post-production for wood 3D prints includes sanding and painting, just like any wooden product.