Is a leaking food package something that you should worry about? This might seem to be a foolish question to most consumers, even to some food-producing businesses. But if you want information about this important but often ignored issue, you’ll find a lot of information about the process. Food sellers do a very good job when they package the items you purchase in the shops but there is always a chance that they got it 99.9% correct, leaving just enough room for concern.

If you’re in this industry or if you’re a consumer who wants to know more about food safety, read on. You’ll find several descriptions of leak detection equipment.

1. Use Helium

This is not about inhaling the contents of a helium balloon so that your voice sounds higher. One of the top methods for leak detection is the helium sniff. The equipment injects the gas into the packaging material under pressure. The test then involves using an electronic helium-detecting scanner to identify if helium is being released into the surrounding air. This test is very useful when you need to know the precise location.

2. Dry Chamber

Another efficient method for discovering leakage is the dry-chamber method, used primarily for liquid products. The liquid (milk, juice) would be placed in an absorbent packaging material. The package is then placed in a vacuum provided by leak detection equipment. It will be evident when the packaging shows liquid, giving the company positive leak detection for food packaging.

3. Listen Closely

You may think that sound would be one of the least-used methods for determining leakage in packaging. But, apart from the obvious sight of leaking or detection by helium “sniffers,” you might also want to look at measurement in the ultrasonic range.

Every leak produces some sound, though the human ear may not hear it because it’s outside the human’s normal range of hearing. Small leaks will produce a high-frequency sound that can be detected by sensitive electronic equipment.

4. Simple but Effective

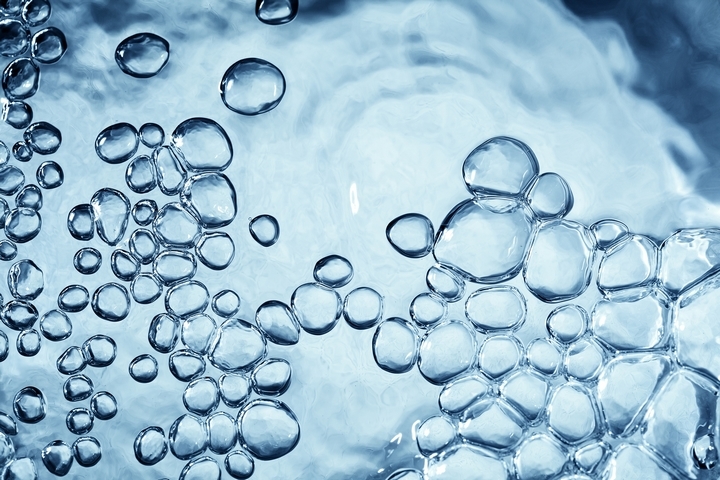

This method is very basic and extremely effective. If you suspect that there is a leak in the material used for packaging food, you can submerge it in water and watch for bubbles rising to the surface of the water. There’s really not much more to say about this. It works.

5. Decay Is the Word

Of course, decay is exactly what you don’t want to happen with your packaged food. But in this case, the word is used to describe two of the tests for leaks in food packaging. This type of leak detection equipment or test puts nitrogen or dry air into the packaging at a set level. The pressure is monitored for a period of time to determine if there is leakage. The vacuum decay test does the opposite, creating a vacuum and then determining if air pressure builds up from that point.

These methods are essential for food safety, especially as people increase their use of packaged food. Making sure that the product remains in its original, safe condition inside the packaging is one of the most important steps in feeding the world.